Robots and collaborative robots (COBOTS) revolutionize industrial automation by combining advanced technology with human collaboration. These sophisticated machines are engineered to perform repetitive tasks with precision and efficiency, freeing human workers to focus on more complex and creative endeavors. With their agility, accuracy, and versatility, robots and COBOTS seamlessly integrate into diverse manufacturing environments, enhancing productivity and throughput. Whether it’s assembly, pick-and-place, or material handling, these robotic systems offer unparalleled reliability and consistency, ultimately leading to improved product quality and reduced cycle times. Moreover, COBOTS are designed to work alongside humans, promoting a safer and more collaborative work environment.

General

Machine tending involves using robots to automate tasks traditionally done by human operators in manufacturing. These tasks include loading and unloading materials, transferring parts between production stages, and handling materials.

ABB has launched its new OmniVance™ Collaborative Machine Tending Cell, providing a complete integrated solution for automated machine tending that is easy to program, install and use. The standardized solution combines a collaborative GoFa™ 12 robot and user-friendly software in a compact solution for fast installation and easy operation.

By automating these repetitive tasks, robots improve efficiency, precision, and safety in production environments. They work continuously without breaks, handle hazardous tasks, and can quickly adapt to different products and processes. Modern machine tending robots integrate with other systems, enabling real-time monitoring and optimization. As technology advances, these robots are becoming more intelligent and collaborative, further enhancing their role in manufacturing.

The combination of industrial robotics and laser marking technologies brings about a new era of automation and customization in manufacturing. Robots can be programmed to position parts accurately for laser marking, ensuring consistency and efficiency. This integration allows for seamless workflows where robotic arms handle the placement and orientation of items, while laser markers execute precise engraving or marking. Such synergy not only speeds up production processes but also enhances the quality and traceability of products.

We use GRACO technologies for our dispensing solutions:

Graco’s comprehensive range of fluid handling solutions demonstrates our commitment to addressing the specific needs of our customers, enhancing productivity, safety, and efficiency across various industries.

SEALANTS & ADHESIVES

Graco provides a complete line of pumping, metering, and dispensing equipment for sealants and adhesives. Our advanced systems ensure precise application and superior bonding performance, critical in automotive, aerospace, construction, and general manufacturing applications.

In the realm of automation manufacturing, precision and efficiency are paramount. Our state-of-the-art screwing solutions embody these principles, leveraging cutting-edge technology from industry-leading brands such as MOUNTZ, ABB Robotics, and TOYO Desktop Robots. This synergy of advanced tools ensures our manufacturing processes are not only reliable but also highly efficient, catering to the stringent demands of modern production environments.

MOUNTZ Torque Products: Precision and Reliability

MOUNTZ Torque products are renowned for their accuracy and durability, critical attributes in automated screwing applications. Torque control is a crucial aspect of any screwing process, ensuring that fasteners are secured with the correct tension to maintain product integrity and safety. MOUNTZ’s torque tools provide:

Consistent Accuracy: High precision in torque application prevents over-tightening or under-tightening, which can lead to component failure.

Durability: Designed to withstand the rigors of high-volume production environments.

Ease of Calibration: Simplified calibration processes to maintain tool accuracy over time.

With MOUNTZ, we achieve exceptional control and reliability, ensuring that every screw is perfectly tightened to specifications, enhancing the overall quality and longevity of our products.

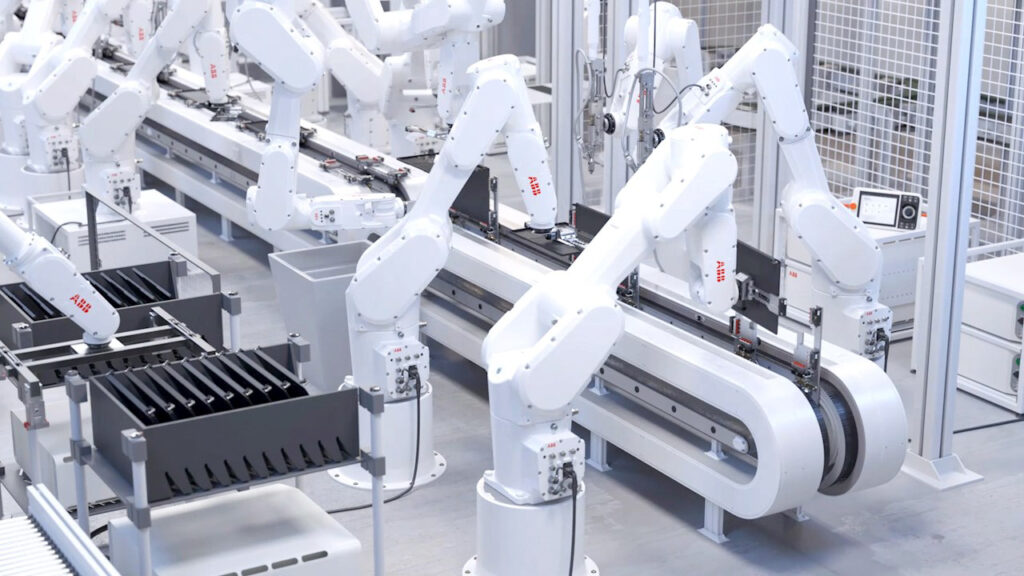

ABB Robotics: Automation Excellence

ABB Robotics products bring a new dimension of efficiency and versatility to our screwing solutions. Renowned for their advanced automation capabilities, ABB robots provide:

High Precision: Advanced robotic arms equipped with sensors and software ensure precise screwing operations, minimizing human error.

Flexibility: Capable of handling a variety of tasks, from small-scale screwing to complex assembly lines.

Scalability: Easily scalable solutions that grow with your manufacturing needs, from small batch productions to large-scale operations.

By integrating ABB Robotics into our manufacturing processes, we streamline operations, reduce cycle times, and enhance productivity, while maintaining the highest standards of accuracy and consistency.

TOYO Desktop Robots: Compact and Versatile

TOYO Desktop Robots complement our screwing solutions by offering compact, versatile automation tools that are ideal for specialized applications. These robots are designed for:

Space Efficiency: Compact design makes them suitable for desktop and small workspaces.

Precision Engineering: High-precision movements and controls ensure meticulous screwing and assembly tasks.

User-Friendly Interface: Intuitive programming and control interfaces simplify integration and operation.

TOYO robots are perfect for tasks that require detailed and delicate handling, providing a reliable solution for intricate screwing applications. Their adaptability and precision make them a valuable asset in any manufacturing setup.

Integrated Solutions for Optimal Performance

By combining MOUNTZ Torque products, ABB Robotics, and TOYO Desktop Robots, we offer an integrated screwing solution that excels in performance and reliability. Our approach focuses on:

Quality Assurance: Ensuring every screw is applied with exact torque, enhancing product durability.

Operational Efficiency: Streamlining processes to reduce production time and costs.

Adaptability: Tailoring solutions to meet specific manufacturing needs, from small-scale operations to extensive production lines.

Our commitment to leveraging the best technologies in the market ensures that our screwing solutions not only meet but exceed industry standards. Trust our expertise and the power of MOUNTZ, ABB, and TOYO to deliver superior automation manufacturing solutions tailored to your needs.

Comprehensive Labeling Solutions

At the core of Novexx’s offerings is its state-of-the-art labeling technology. Novexx Solutions provides robust and versatile label printers, applicators, and integrated systems that ensure precise and reliable labeling across a wide range of products and packaging types. Their solutions are designed to handle high-speed production environments, delivering consistent performance even under the most demanding conditions.

Advanced Printing Technologies

Novexx excels in delivering high-quality printing solutions tailored to meet the specific requirements of various industries, including food and beverage, pharmaceuticals, logistics, and manufacturing. Their printers are engineered to produce sharp, durable, and legible prints, ensuring that labels remain clear and compliant with industry standards throughout the product lifecycle. Whether it’s barcodes, QR codes, or complex graphics, Novexx printing solutions guarantee optimal results.

Tracking and Traceability

In an era where supply chain transparency and product traceability are critical, Novexx Solutions offers robust tracking systems that provide end-to-end visibility. These systems enable businesses to monitor and trace their products at every stage of the supply chain, ensuring accountability and reducing the risk of counterfeiting and errors. Novexx’s traceability solutions support compliance with stringent regulatory requirements and enhance overall operational efficiency.

Flexible Automation

FlexiBowl® is the flexible feeder that orients and separates parts by exploiting the movements of a rotating plate actuated by a servomotor and a pulse generator.

It can feed products of any geometry, surface and material. It is compatible with all industrial robots and vision systems.

One FlexiBowl® can feed entire ranges of parts measuring between 1-300 mm and 1-300 g, replacing the need for numerous units as in conventional systems.

FlexiBowl® is available in 6 models.

ABB’s commitment to advancing robotics technology is evident in its extensive portfolio of robotic solutions. From small-scale operations to large industrial applications, ABB robots are designed to meet the diverse needs of manufacturers worldwide. These robots are equipped with cutting-edge features, including advanced motion control, real-time data analytics, and artificial intelligence, enabling them to perform complex tasks with unmatched accuracy and speed.

ABB’s commitment to advancing robotics technology is evident in its extensive portfolio of robotic solutions. From small-scale operations to large industrial applications, ABB robots are designed to meet the diverse needs of manufacturers worldwide. These robots are equipped with cutting-edge features, including advanced motion control, real-time data analytics, and artificial intelligence, enabling them to perform complex tasks with unmatched accuracy and speed.

The versatility of ABB robots is one of their defining characteristics. They are employed in a wide array of industries, including automotive, electronics, pharmaceuticals, food and beverage, and logistics. Whether it’s assembling intricate electronic components, welding automotive parts, or handling delicate pharmaceutical products, ABB robots excel in delivering high performance under varying operational conditions.

At Unlimited Electro Group, we proudly represent Mech-Mind Robotics, a trailblazing company in the world of industrial robotics. Mech-Mind specializes in cutting-edge 3D cameras and AI-powered software solutions that are revolutionizing automation across industries. With the fusion of 3D vision and AI, Mech-Mind takes automation to new heights, enabling partners and system integrators to conquer even the most intricate tasks, from bin picking to assembly and inspection.

📷 Mech-Eye Industrial 3D Cameras: Offering high resolution, accuracy, and ruggedness, our cameras are designed for challenging factory environments. They provide dust and water protection, reliable performance, and easy setup for a range of robotic applications.

Guided by Mech-Mind 3D vision system, robots can recognize randomly-piled materials, even those with dark or reflective surfaces and complex structures, and then pick them up from deep bins accurately without damaging the components.

Guided by Mech-Mind 3D vision system, robots can recognize randomly-piled materials, even those with dark or reflective surfaces and complex structures, and then pick them up from deep bins accurately without damaging the components.

Flexible cutting

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

End of Line Packaging

Advanced Palletizing Solutions

ABB’s palletizing robots are designed to handle a wide range of products, from small, lightweight items to heavy, bulky goods. These robots are equipped with sophisticated sensors, precision control systems, and robust mechanical arms, enabling them to perform complex palletizing tasks with high speed and accuracy. ABB offers a variety of palletizing robots, each tailored to specific needs and applications, ensuring optimal performance in diverse operational environments.

Key Features and Capabilities

High Speed and Precision: ABB palletizing robots are capable of performing rapid and precise stacking operations, significantly increasing throughput and reducing cycle times. This efficiency is crucial for meeting the demands of high-volume production and distribution environments.

Versatility: ABB’s palletizing solutions are highly versatile, capable of handling different product shapes, sizes, and weights. This flexibility allows businesses to adapt to varying product lines and packaging requirements without needing extensive reconfiguration.

Ease of Integration: ABB robots are designed for seamless integration into existing production lines and warehouse systems. Their user-friendly interfaces and programming tools make it easy to set up and adjust palletizing operations, minimizing downtime and enhancing overall productivity.

Advanced Gripping Technology: Equipped with specialized grippers, ABB palletizing robots can securely handle products with diverse characteristics, including fragile items and irregularly shaped goods. This advanced gripping technology ensures safe and reliable palletizing, reducing the risk of product damage.

Enhanced Safety Features: ABB prioritizes safety in its robotic solutions. Palletizing robots are equipped with advanced safety systems, including collision detection and safety-rated monitored stop functions, ensuring safe operation around human workers and other machinery.

MORE SERVICES

UL – 508A

Control Boards

Robots/Cobots

For all types of applications