A UNO TEC, designs and realizes customized automatic machines for the assembly of medical devices, in plastic materials in clean rooms. Specializing in Infusion Therapy and Dialysis, it constitutes a benchmark in the development of solutions for the assembly of medical products required by the manufacturing medical market. The wide variety of clients, spread across the world, has contributed to enrich its technical knowledge and innovating capability, ensuring an efficient turnkey service.

BANDY SYSTEMS

- BANDY CUT

- CCB MINI

- CCB MAXI

- BANDY PRINT

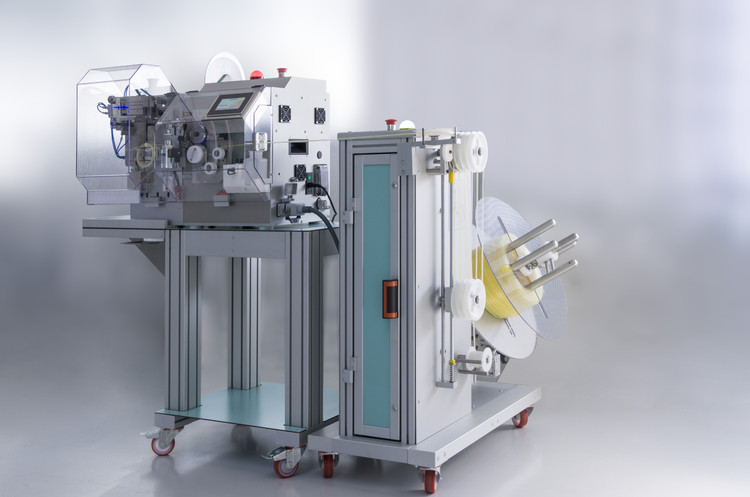

BANDYCUT (Cutting Solution)

BANDY System is a flexible-modular solution based on 4 main working units operating in sequence.

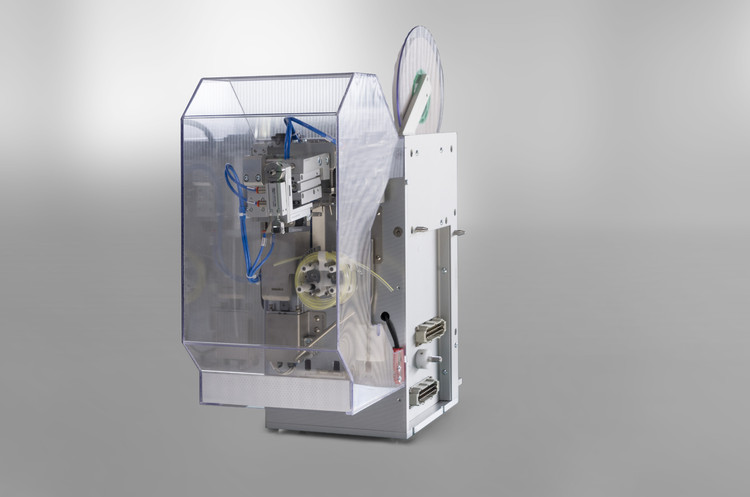

Cutting Unit (BANDYCUT) s the core of the system and manages additional Coiler & Bander (BANDYCCB) and Printer (BANDYPRINT).

In-house tubing cutting is crucial and convenient whenever looking to optimize the production and related costs.

Any cutting machine allows to plan properly the lean production from the early beginning, tuning it quickly up to any possible scenario.

As stand-alone equipment, provided completed with its motorized uncoiler, BANDYCUT can also work in-process on the benchtop (e.g.: tubing cutting for instant manual assembling of components by the operator). In this view it is possible to program sequences in order to get different lengths cyclically.

Working principle:

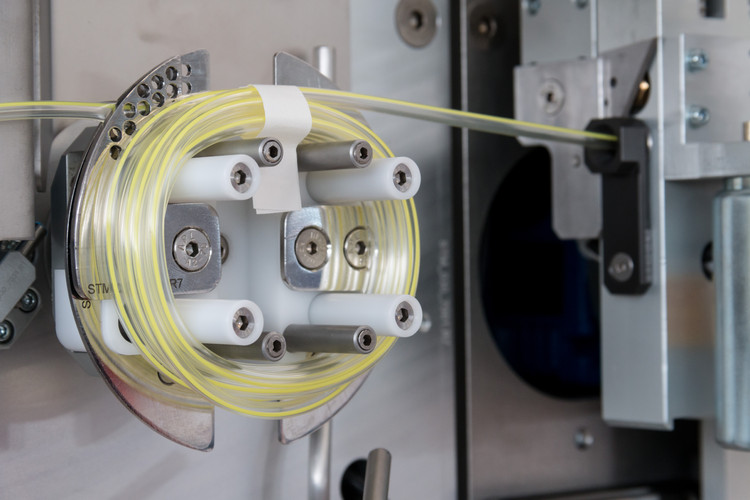

Uncoiling the tubing from Reels (the Motorized Uncoiler constantly ensures around 2 meters of detensioned-unstressed Tubing).

Cutting the tubing to specific length according to the selected program.

Automatic discharging of the tubes (collecting conveyor belt available as option).

Technical features:

- Automatic cutting of tubing with outer diameter included in the range 2 – 10 mm *

- Cutting length adjustable between 10 and 99999 mm *

- Batch programming and counting of number of pieces per box

- Cutting speed (e.g.):

– up to 13.200 pcs/h, tube length 30 mm *

– up to 7.920 pcs/h, tube length 300 mm *

– up to 2.160 pcs/h, tube length 1500 mm *

- Standard blades to pursue cost saving and local findability

* Suitability and performance may change according to tubing specifications to be processed

BANDYCUT is the core of BANDY System, it is possible to add Coiling & Banding unit (BANDYCCB) and Printer (BANDYPRINT) whenever required.

BANDYCCB Mini (Cutting – Coiling – Banding Solution)

BANDY System is a flexible-modular solution based on 4 main working units operating in sequence.

Cutting Unit (BANDYCUT) is the core of the system and manages additional Coiler & Bander (BANDYCCB) and Printer (BANDYPRINT).

Small coils are convenient when moved and handled in clean room for any process, including packaging purpose.

Moreover cohesive tape wrapping is easy and safe to be removed whenever required.

BANDYCCB is highly indicated to improve productivity and quality of sub-assemblies which are part of infusion sets, heparin and extension lines, etc.

Tubing length, coil diameter, free tubing ends length, tape position and coil configuration can be programmed and adjusted.

BANDYCCB Mini can process tubing of different elastomers with external diameter up to 4.1 mm * and band it with 1/2” (13 mm) width medical grade cohesive tape (with Latex or Latex-free).

Working range can be extended up to 10 mm tubing OD thanks to BANDYCCB MAXI and/or specific customizations.

Working principle:

Uncoiling the tubing from Reels (the Motorized Uncoiler constantly ensures around 2 meters of detensioned-unstressed Tubing).

Cutting and Coiling the tubing according to the selected program.

Banding the Coil (with no. 1 or no. 2 pieces of cohesive tape) according to the specifications required.

Automatic discharging of the coils (conveyor belt available as option).

Technical Features:

- Suitable with tubing OD included in the range 2 – 4,1 mm *

- Tubing length to be coiled adjustable in the range 250 – 2000 mm (according to tubing OD 4.1) *

- Coil dimensions: adjustable ID in the range 45 – 70 mm *

- Nominal productivity 750 pcs/h (according to tubing OD 4.1 mm, tube length 1500 mm, single fastening) **

- Cohesive paper width 1/2” (13 mm), 3 fastening configurations available (shape: “C” with 2 tapes, “T” with 1 or 2 tapes)

- Setting of parameters via touch screen display of the cutting unit

- Quick-lock-release system for connection to the cutting unit

* General info provided, since the working range is bound to the specification of both tubing and final coil.

** Productivity changes according to tube length and fastening configuration.

BANDYCCB Mini can work as stand-alone Cutting Equipment.

The Quick-lock-release system allows to unplug (and plug) the Banding & Coiling unit safely and easily.

Moreover, it is possible to add the Printer (BANDYPRINT) whenever required.

BANDYCCB Maxi (Cutting – Coiling – Banding Solution)

BANDY System is a flexible-modular solution based on 4 main working units operating in sequence.

Cutting Unit (BANDYCUT) is the core of the system and manages additional Coiler & Bander (BANDYCCB) and Printer (BANDYPRINT).

Coils are convenient when moved and handled in clean room for any process, including packaging purpose.

Moreover cohesive tape wrapping is easy and safe to be removed whenever required.

BANDYCCB is highly indicated to improve productivity and quality of sub-assemblies which are part of infusion sets, heparin and extension lines, etc.

Tubing length, coil diameter, free tubing ends length, tape position and coil configuration can be programmed and adjusted.

BANDYCCB MAXI can process tubing of different elastomers with external diameter up to 10.0 mm and fasten coils with 1/2” (13 mm) or 1” (25 mm) width medical grade cohesive tape (with Latex or Latex-free).

For small tubing and coils please also check smart-compact BANDYCCB Mini.

Working principle:

Tubing uncoiling from Reels (the Motorized Uncoiler constantly ensures around 2 meters of detensioned-unstressed Tubing).

Tubing cutting and coiling according to the selected program.

Coil banding (with no. 1 or no. 2 pieces of cohesive tape) according to the specifications required.

Coils automatic discharging (conveyor belt available as option).

Technical Features:

- Suitable with tubing OD included in the range 2 – 10 mm *

- Tubing length to be coiled adjustable in the range 500 – 8000 mm (depending on tubing OD and coil ID) *

- Coil dimensions: adjustable ID in the range 75 – 150 mm *

- Nominal productivity 530 pcs/h ** (according to tubing OD 4.1 mm, tube length 1500 mm), single as well as simultaneous-double fastening

- Cohesive paper width 1/2″ or 1” (13 or 25 mm), 3 fastening configurations available (shape: “C” with 2 tapes, “T” with 1 or 2 tapes)

- Setting of parameters via touch screen display of the cutting unit

- Quick-lock-release system for connection to the cutting unit

* General info provided, since the working range is bound to the specification of both tubing and final coil.

** Productivity changes according to tube length and fastening configuration.

BANDYCCB MAXI can work as stand-alone Cutting Equipment.

The Quick-lock-release system allows to unplug (and plug) the Banding & Coiling unit safely and easily.

Moreover, it is possible to add the Printer (BANDYPRINT) whenever required.

BANDYPRINT (Cutting – Printing Solution)

BANDY System is a flexible-modular solution based on 4 main working units operating in sequence.

Cutting Unit (BANDYCUT) is the core of the system and manages additional Coiler & Bander (BANDYCCB) and Printer (BANDYPRINT).

Marking the tubing is required when producing catheters and drainage and suction devices.

Moreover, any customization could be smart looking to highlight products over the market from competitors as well as for adding information such as production data, expiration date, etc.

Working principle:

Tubing uncoiling from Reels (the Motorized Uncoiler constantly ensures about 2 meters of detensioned-unstressed Tubing).

Tubing printing with text synchronization according to length to cut.

Tubing cutting as per selected program.

Tubes automatic discharging (collecting conveyor belt available as option).

Main printing features:

- Quick dry to allow instant handling and processing

- Constant accuracy and print quality over time

- Dedicated built-in Touchscreen offering easy-to-understand icons graphics menu with “WYSIWYG” view print messages. 48 messages message storage capacity (Option: up to 1,000 messages, depending on data content)

- Nozzle size 65 µm

- Up to 120 characters maximum number of print characters (Option: up to 1,000 characters) *

- Character height 2-10 mm *

- Printing of standard alphanumeric characters (A-Z, a-z, 0-9), symbols, including barcodes *

- Print function such as Calendar, Count, Font mixture, Password security, etc. *

- Simplicity of operations, the operator finds everything at hand and accessible: ink and solvent tanks, parts subject to preventive maintenance

Technical cutting features:

- Automatic cutting of tubing with outer diameter included in the range 2 – 10 mm *

- Cutting length adjustable between 10 and 99999 mm *

- Batch programming and counting of number of pieces per box

- Cutting speed (e.g.):

– up to 13.200 pcs/h, tube length 30 mm *

– up to 7.920 pcs/h, tube length 300 mm *

– up to 2.160 pcs/h, tube length 1500 mm *

- Standard blades to pursue cost saving and local findability

* Suitability and performance may change according to tubing and text specifications to be processed.

BANDYPRINT can also work just as Cutting Equipment (BANDYCUT), without printing.

It is possible to add the Coiling and Banding unit (BANDYCCB) whenever required.