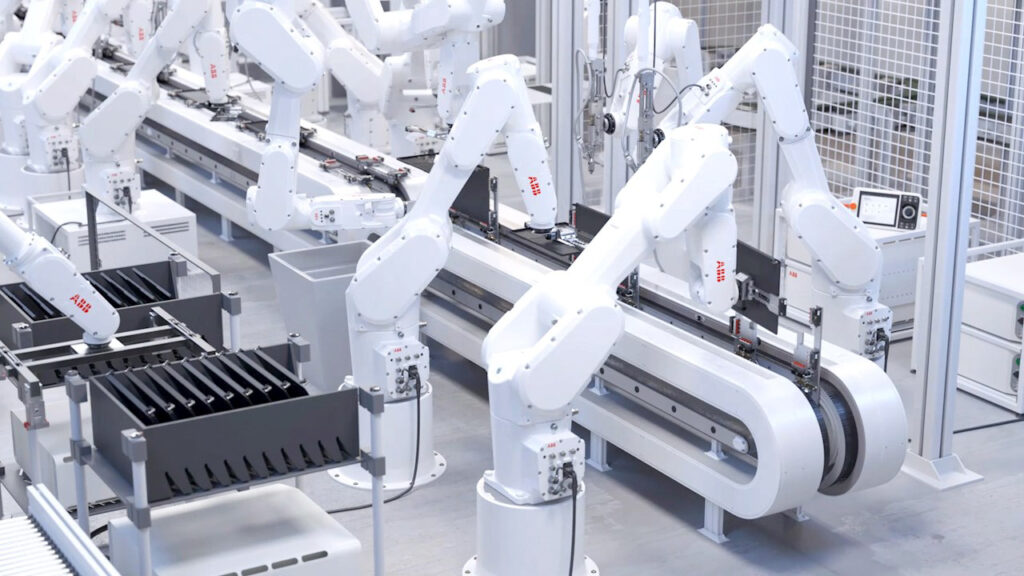

Feeding solutions, encompassing industrial bowl feeders and hopper feeders, are integral components of automated manufacturing processes, ensuring the smooth and consistent supply of components to production lines. These meticulously engineered systems efficiently handle a wide range of parts, from small screws to larger components, with precision and reliability. Industrial bowl feeders utilize vibration and centrifugal force to orient and align parts, optimizing the feeding process for seamless integration into assembly lines. Hopper feeders, on the other hand, offer versatility by accommodating bulk quantities of parts and releasing them in a controlled manner to meet production demands. With their customizable designs and adjustable settings, feeding solutions can adapt to various part sizes and shapes, enhancing efficiency and reducing downtime. By automating the feeding process, manufacturers can significantly increase throughput, improve product quality, and streamline operations.

Flexibowl

Bowl Feeders

Elevator Feeders

Hopper Feeders

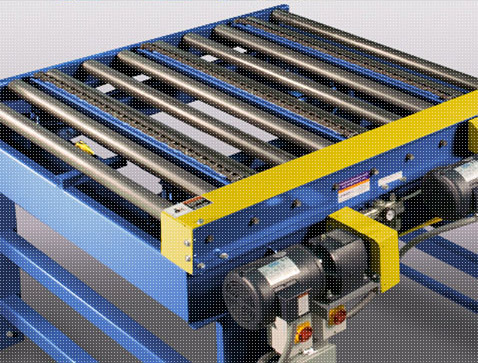

Conveyors